Basic Info.

Model NO.

ASTM A179/A192 ST37 ST35.8 T5 T12 T22

Usage

Pipeline Transport, Boiler Pipe, Hydraulic/Automobile Pipe, Oil/Gas Drilling, Machinery Industry, Chemical Industry, Mining, Construction & Decoration

Section Shape

Round

Wt

1.0-30mm

Length

2-20meters

Loading Port

Tianjin/Shanghai/Qingdao

Steel Grade 1

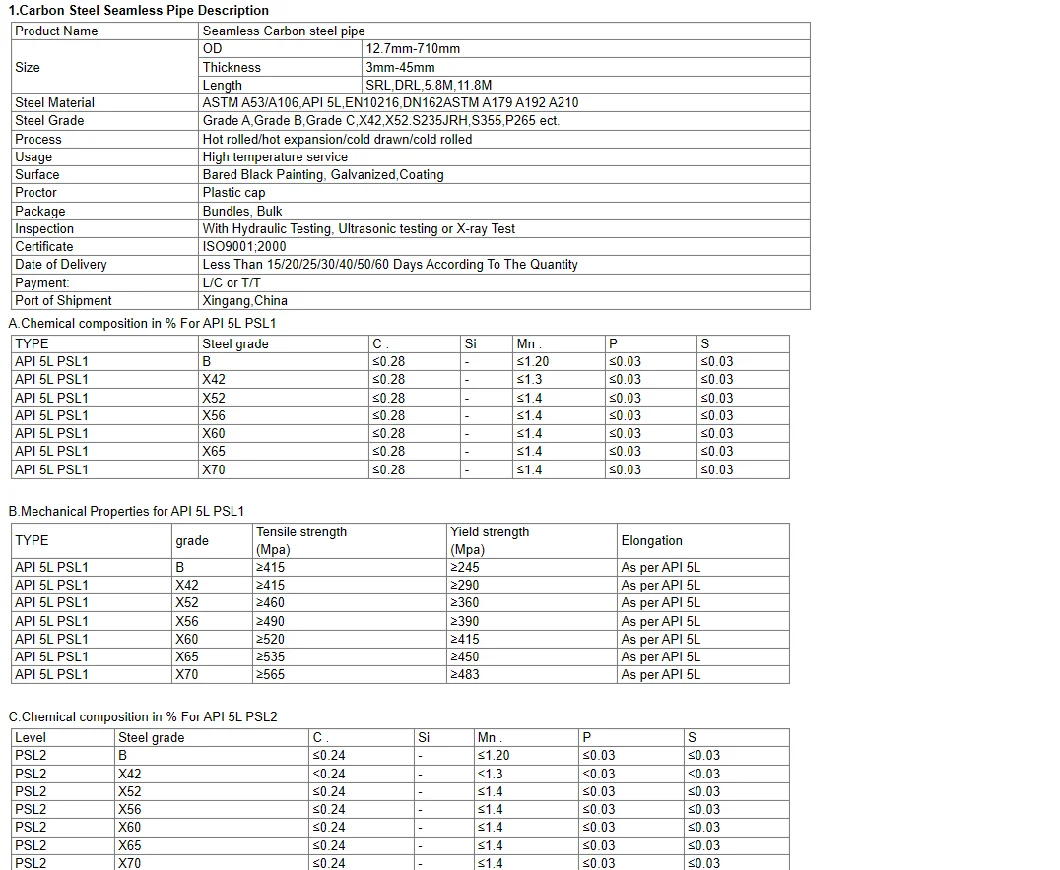

API 5L ASTM A106/A53 Gr.B /X42/X52/X65/X60

Steel Grade 2

ASME SA789uns S31803, Uns S32205, Uns S31500, Uns

Steel Grade 3

A333 Gr.6 A335 P5 SA199/SA213 T5 P11 T22

Carbon Steel Production

80000tons/Year

Stainless Steel Production

15000tons/Year

Alloy Steel Production

30000tons/Year

Casing&Tubing

100000tons/Year

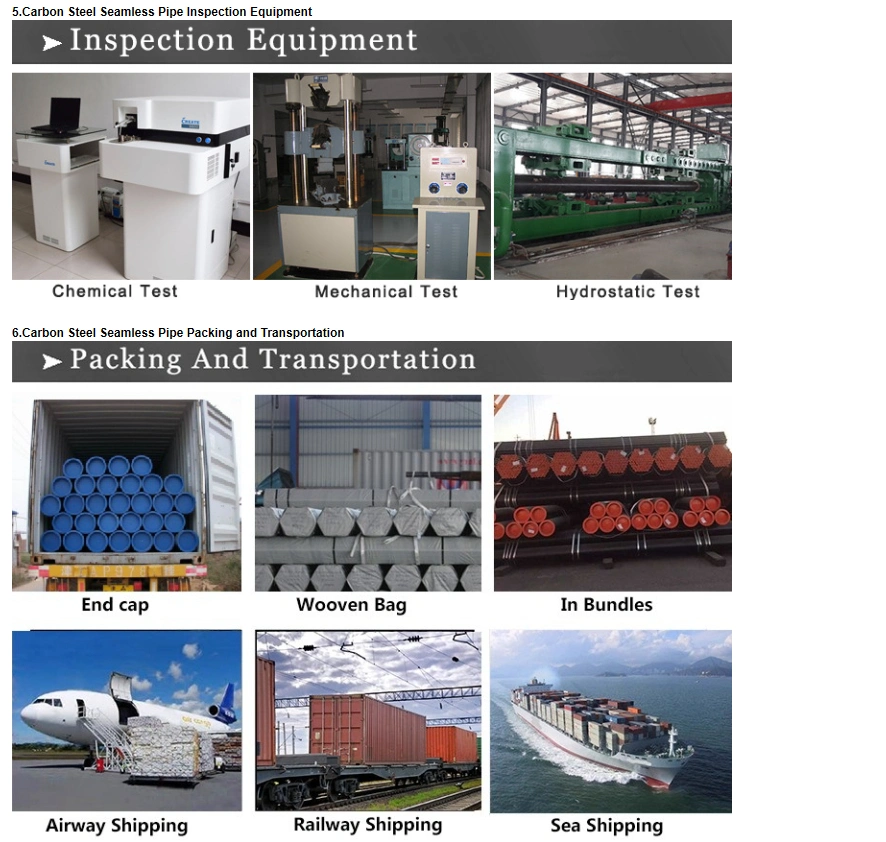

Transport Package

Galvanized Steel Strip&Wooden Case in Bundle,

Specification

OD50.8MM/63.5MM*WT3.18MM/3.5MM

Trademark

OEM/TJTC

Origin

Hebei/Anhui/Jiangsu/Zhejiang

HS Code

7304193000

Production Capacity

80000&15000&30000&100000tons

Product Description

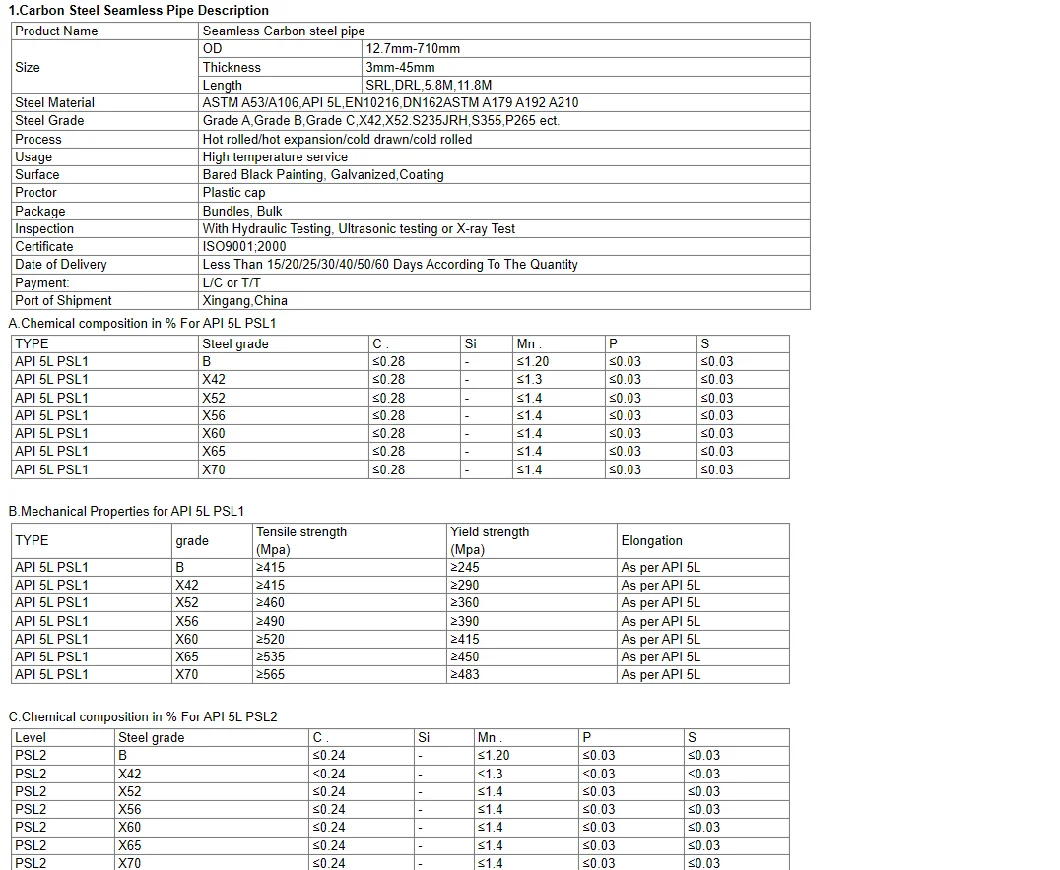

Boiler Steel Tube, Boiler Tube

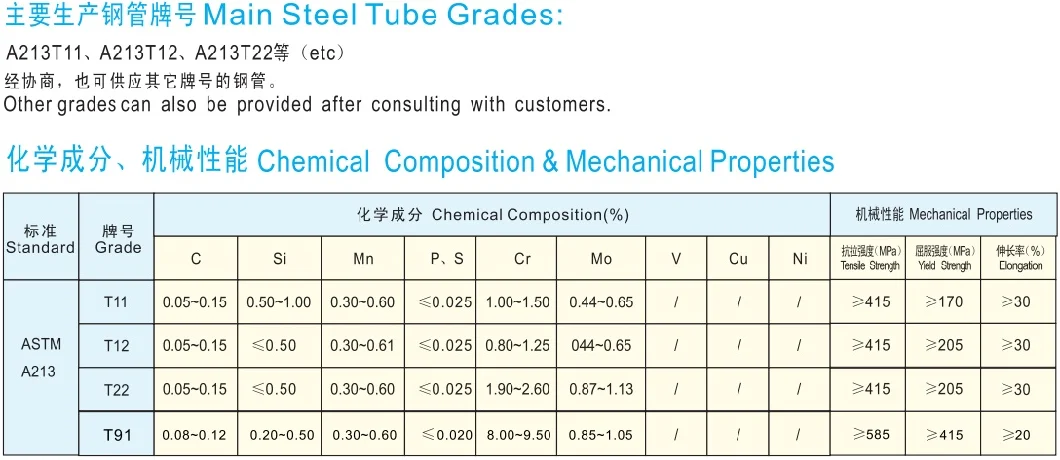

Standard and Steel Grade:

ASTM A106/ASME SA106 Grade B, Grade C;

ASTM A179/ASME SA179;

ASTM A192/ASME SA192;

ASTM A210/ASME SA210 Grade A1, Grade C;

ASTM A333/ASME SA333 Grade 6;

ASTM A209/ASME SA209 Grade T1, T1a, T1b;

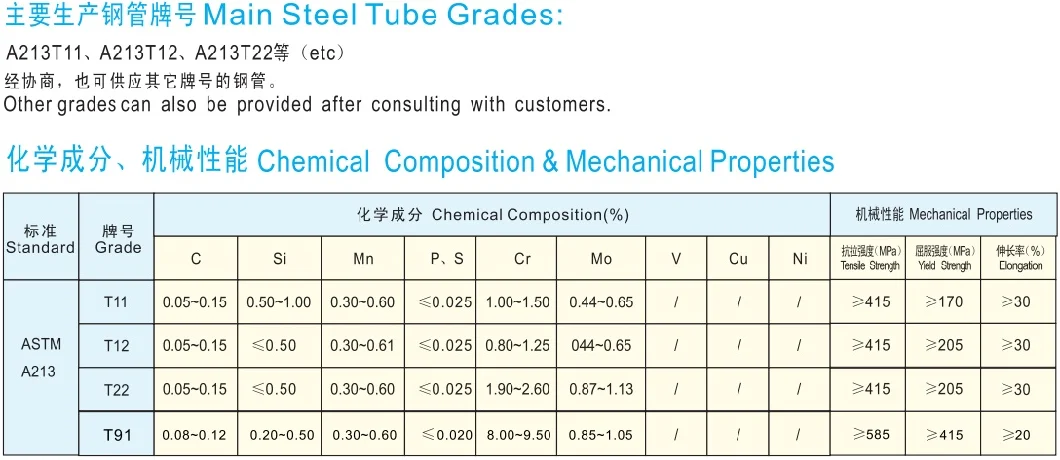

ASTM A213/ASME SA213 T2, T11, T12, T22, T91, T92;

ASTM A335/ASME SA335 P5, P9, P11, P12, P22, P91, P92;

DIN17175 St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910;

EN10216-2 P195GH, P235GH, P265GH;

Size: OD10-168mm X WT1-18mm

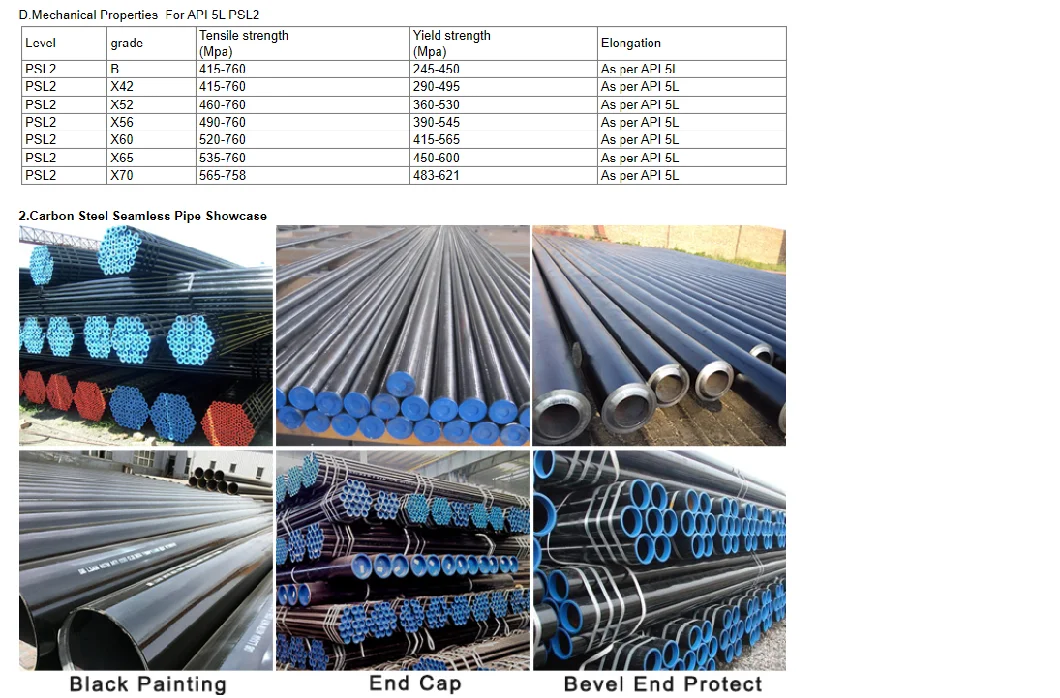

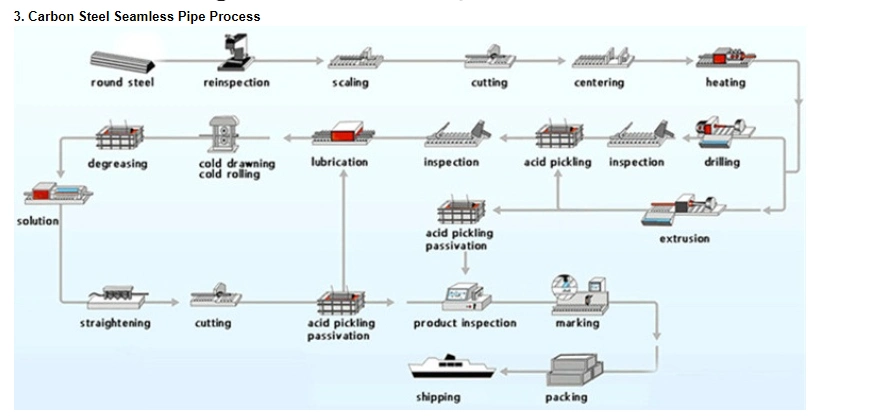

Manufacturing Method: Cold Drawn, Hot Rolled.

Application: For manufacturing boiler, reheater, superheater, heat exchanger, condenser, etc.

SA179/SA192 CHEMICAL AND MECHANICAL COMPONENT:

Standard and Steel Grade:

ASTM A106/ASME SA106 Grade B, Grade C;

ASTM A179/ASME SA179;

ASTM A192/ASME SA192;

ASTM A210/ASME SA210 Grade A1, Grade C;

ASTM A333/ASME SA333 Grade 6;

ASTM A209/ASME SA209 Grade T1, T1a, T1b;

ASTM A213/ASME SA213 T2, T11, T12, T22, T91, T92;

ASTM A335/ASME SA335 P5, P9, P11, P12, P22, P91, P92;

DIN17175 St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910;

EN10216-2 P195GH, P235GH, P265GH;

Size: OD10-168mm X WT1-18mm

Manufacturing Method: Cold Drawn, Hot Rolled.

Application: For manufacturing boiler, reheater, superheater, heat exchanger, condenser, etc.

SA179/SA192 CHEMICAL AND MECHANICAL COMPONENT:

| ASTM A179/(ASME SA179) | |

| Seamless Cold Drawn Low Carbon Steel Heat Exchanger And Conderser Tubes | |

| Application: | For tubular heat exchangers,condensers,and similar heat transfer apparatus. |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 12000 |

Grade and Chemical Composition (%)

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Tolerance(SA-450/SA-450M):

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |

ASTM A192/A192M-02 | |

| Seamless Carbon Steel Bolier Tubes for High-Pressure | |

| Application: | For seamless carbon steel bolier and superheater tubes for high-pressure service |

| Size(mm): | O.D.:6.0~114.0 W.T.:1~15 L:max 12000 |

Grade and Chemical Composition (%)

| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Tolerance(SA-450/SA-450M):

| OD In (mm) | + | - | WT In(mm) | + | - |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1~1.1/2(25.4~38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2~<2(38.1~50.8) | 0.20 | 0.20 | |||

| 2~<2.1/2(50.8~63.5) | 0.25 | 0.25 | |||

| 2.1/2~<3(63.5~76.2) | 0.30 | 0.30 | |||

| 3~4(76.2~101.6) | 0.38 | 0.38 | |||

| >4~7.1/2(101.6~190.5) | 0.38 | 0.64 | |||

| >7.1/2~9(190.5~228.6) | 0.38 | 1.14 |